While some businesses claim to be sustainable, few “walk the talk” in the way that Fronius, a European inverter manufacturer, does. The business is ambitious in its plans to reduce the environmental footprint of its products, replacing “take-make-waste” with a circular design embodied in the United Nations’ Sustainable Development Goal 12.

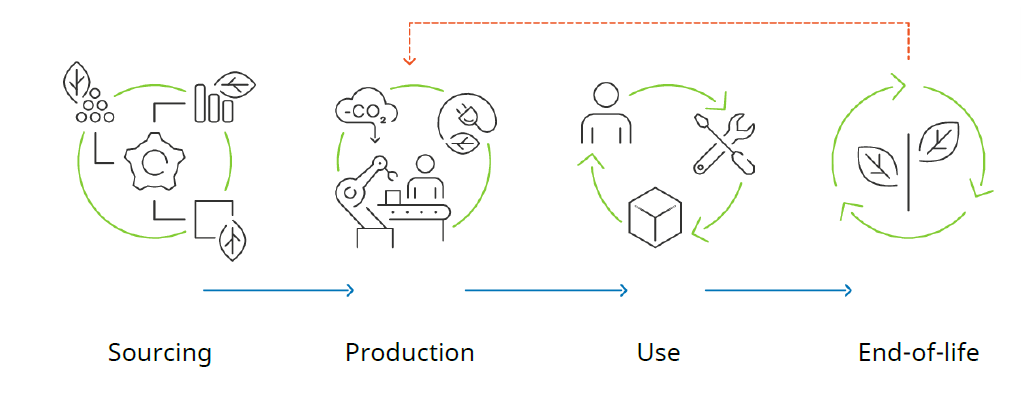

To achieve this a fact-based understanding of Fronius products’ sustainability performance is needed. A Life Cycle Assessment is one of the most common and internationally standardized scientific methods to analyse the environmental influences of a product throughout its lifetime.

In 2020, the first Fronius Life Cycle Assessment (LCA) for one of its inverter generations, the Fronius GEN24 [Plus] was published. Carried out by Fraunhofer, assessment looks at all stages of the product life cycle, These stages are sourcing of raw materials, production at Fronius sites, transportation, the use phase and end-of-life phase.

The assembly of the inverter at the Fronius production sites in Austria or Czechoslovakia represents only a limited proportion of the carbon footprint (0.7%). This proves that the assembly process is already optimized. The production sites are 100% powered by renewable energy with 3500MWh of energy generated from solar PV installed on the building roofs.

More than 90% of recycled aluminium is used in the main metallic component of the inverter. Using recycled aluminium saves around 45% of the CO2 used in its manufacture. 99% of the waste is either reused or recycled.

Repair instead of replacement

Where Fronius really stands out is the design approach that allows parts to be easily exchanged on-site if they become faulty, rather than replacing the entire unit. If a Tauro inverter becomes defective after 10 years, one repair generates a maximum of 147kg of CO2 emissions. The exchange of the entire inverter, on the other hand, would have resulted in 1,133kg of CO2 emissions.

The fan and data communication unit are components that could be replaced during the unit’s 20 year lifetime. The inverter cover is removed to expose the fan, behind which is the heat sink and then the data communication unit. There’s easy access to these parts so that the exchange can be done quickly and efficiently by Solarkinetics.

As a Fronius Service Partner, all Solarkinetics electricians are trained on repairing the Fronius units, with parts sourced in the UK from the Fronius Milton Keynes facility.